PRE-SHIPMENT INSPECTION

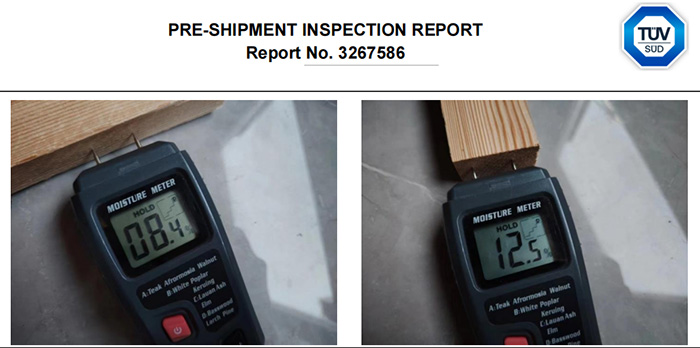

Wood Moisture Testing

In our factory, every sofa wood frame undergoes rigorous moisture testing before mass production. Using advanced moisture meters, we ensure the wood's humidity level is within the optimal range (typically 8-12%). This prevents warping, cracking, or mold, guaranteeing durable and stable furniture that meets international quality standards.

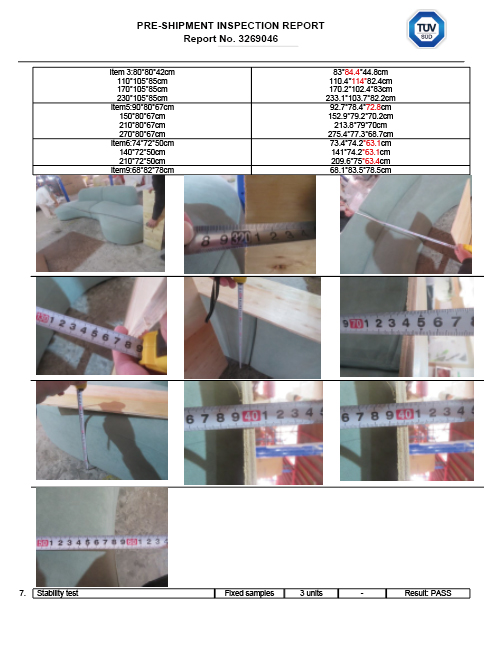

Pre-Production Size Measurement

Before mass production, our team meticulously measures every sofa design to ensure precise dimensions.This step guarantees perfect fit, consistency, and compliance with client specifications, ensuring high-quality, error-free furniture.

Load-Bearing Testing

Before mass production, our sofas undergo rigorous load-bearing tests to ensure durability and safety. We simulate long-term use with weighted pressure, verifying frames and joints can withstand daily wear, meeting international standards for strength and reliability.

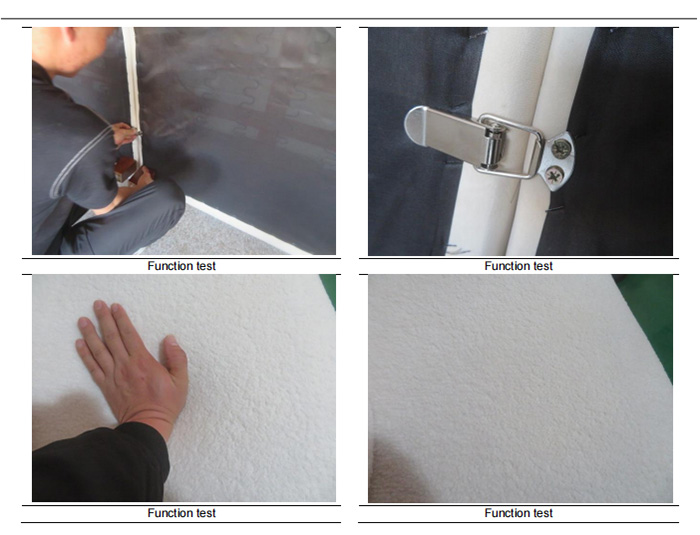

Functionality Testing

Before mass production, our sofas undergo comprehensive functionality tests to ensure smooth operation of mechanisms like recliners, pull-out beds, or adjustable headrests. We verify ease of use, durability, and safety, delivering reliable and user-friendly furniture.